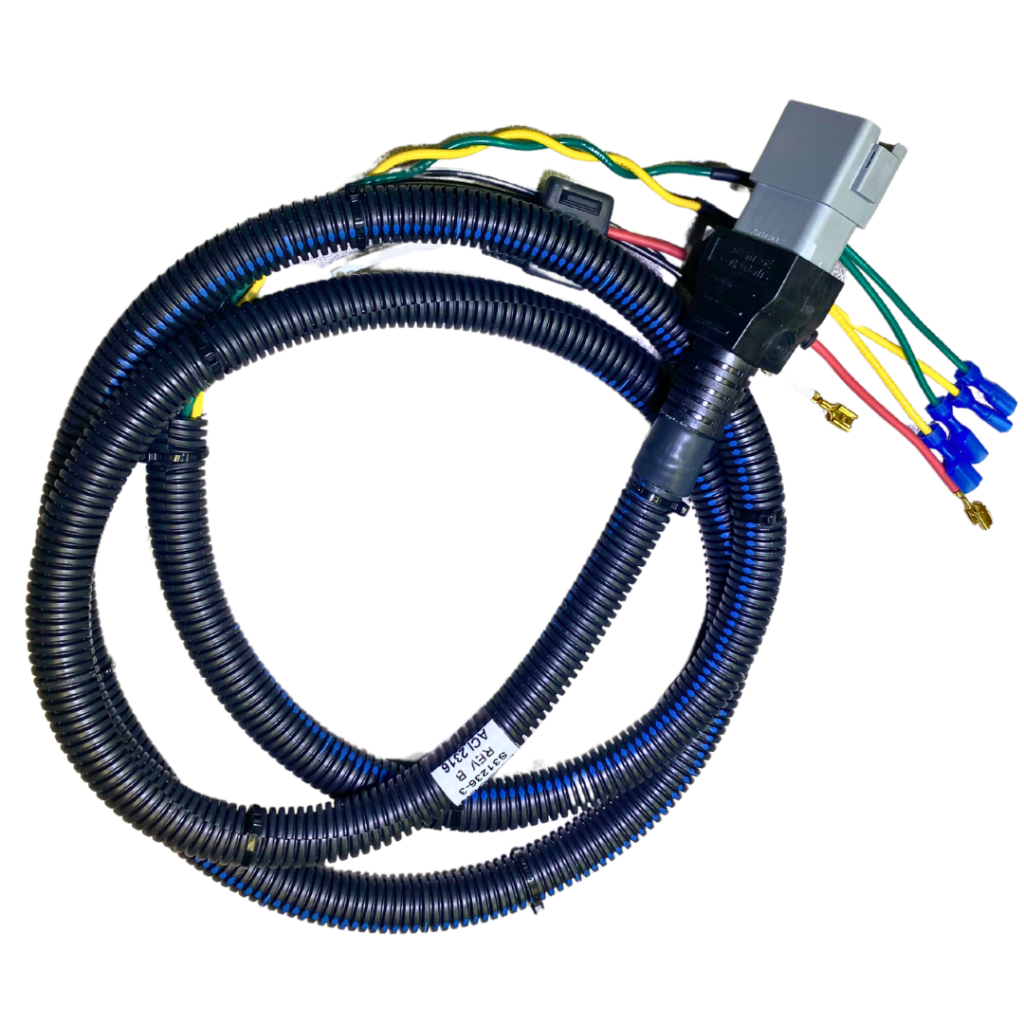

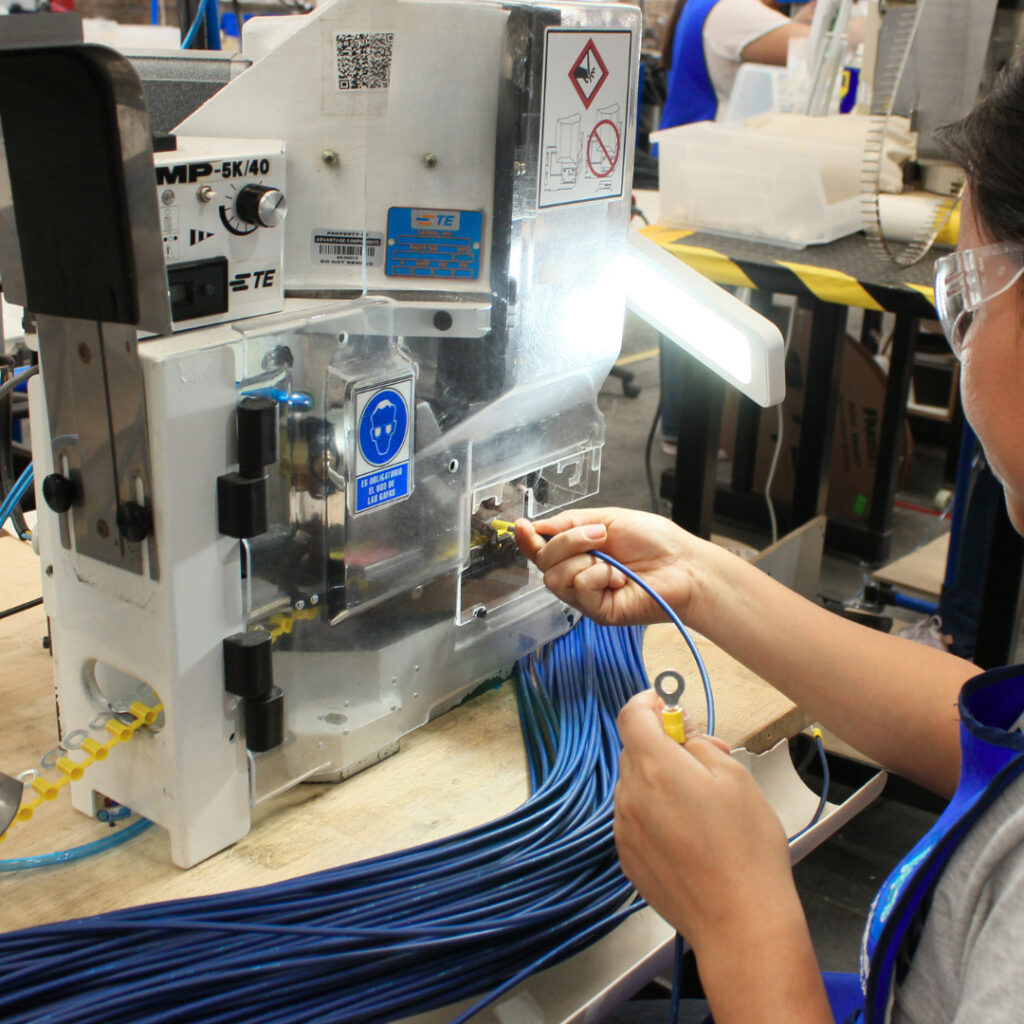

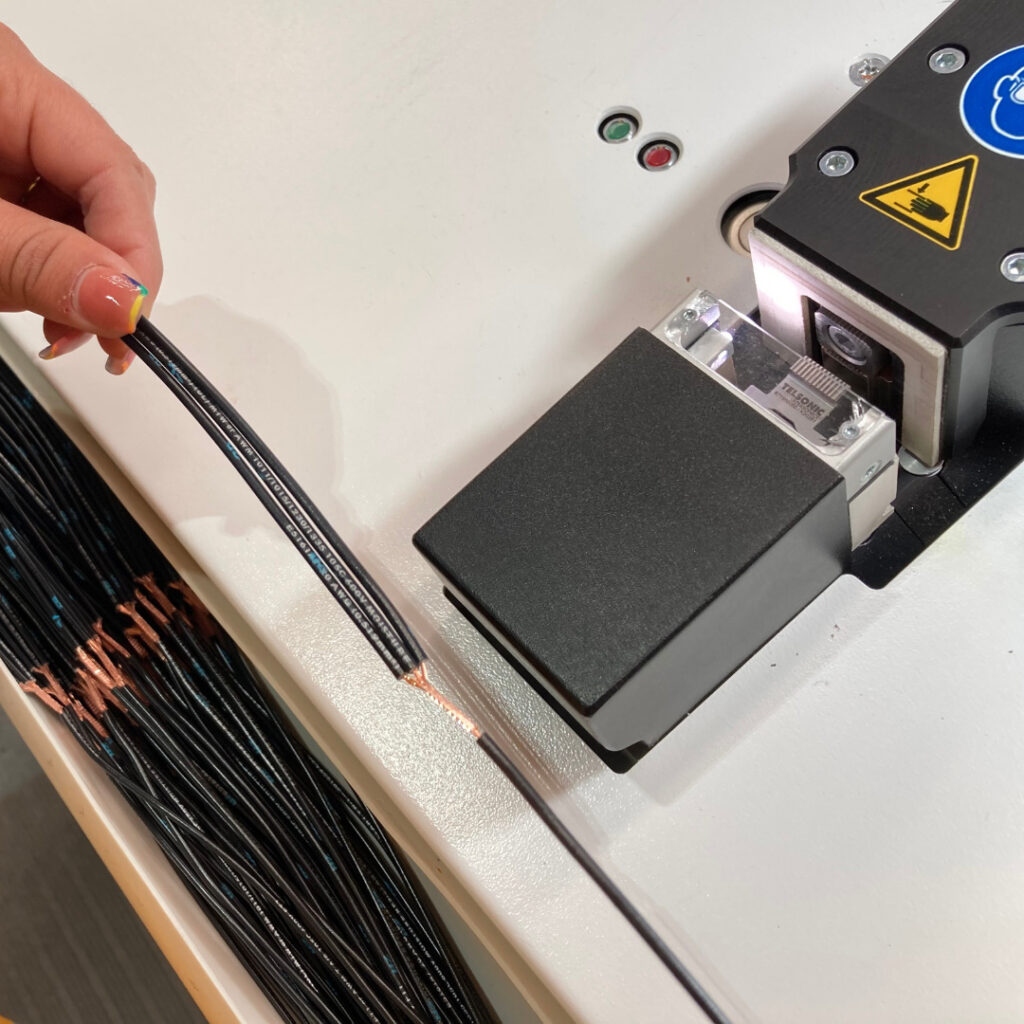

Wire Harness Solutions

Whether you’re seeking engineering support for a large, complex wire harnesses or have a ready-to-build design, ACI is here to help at any stage of your project. Explore the various ways support can be provided for your wire harness needs below.

Get a Quote

To request a quote or contact us, please complete the form below and we will get back to you within 1 business day.

*Please note that we have an MOQ of 50 pcs*

If you are uploading a large file, the form could take some time to submit.