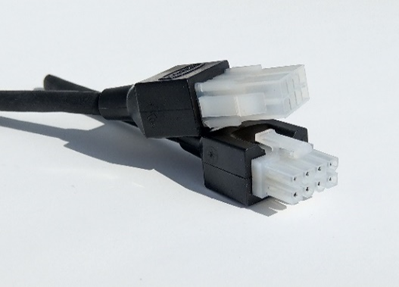

- Low Pressure Molding is an alternate process to the more common high pressure process.

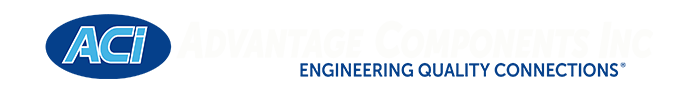

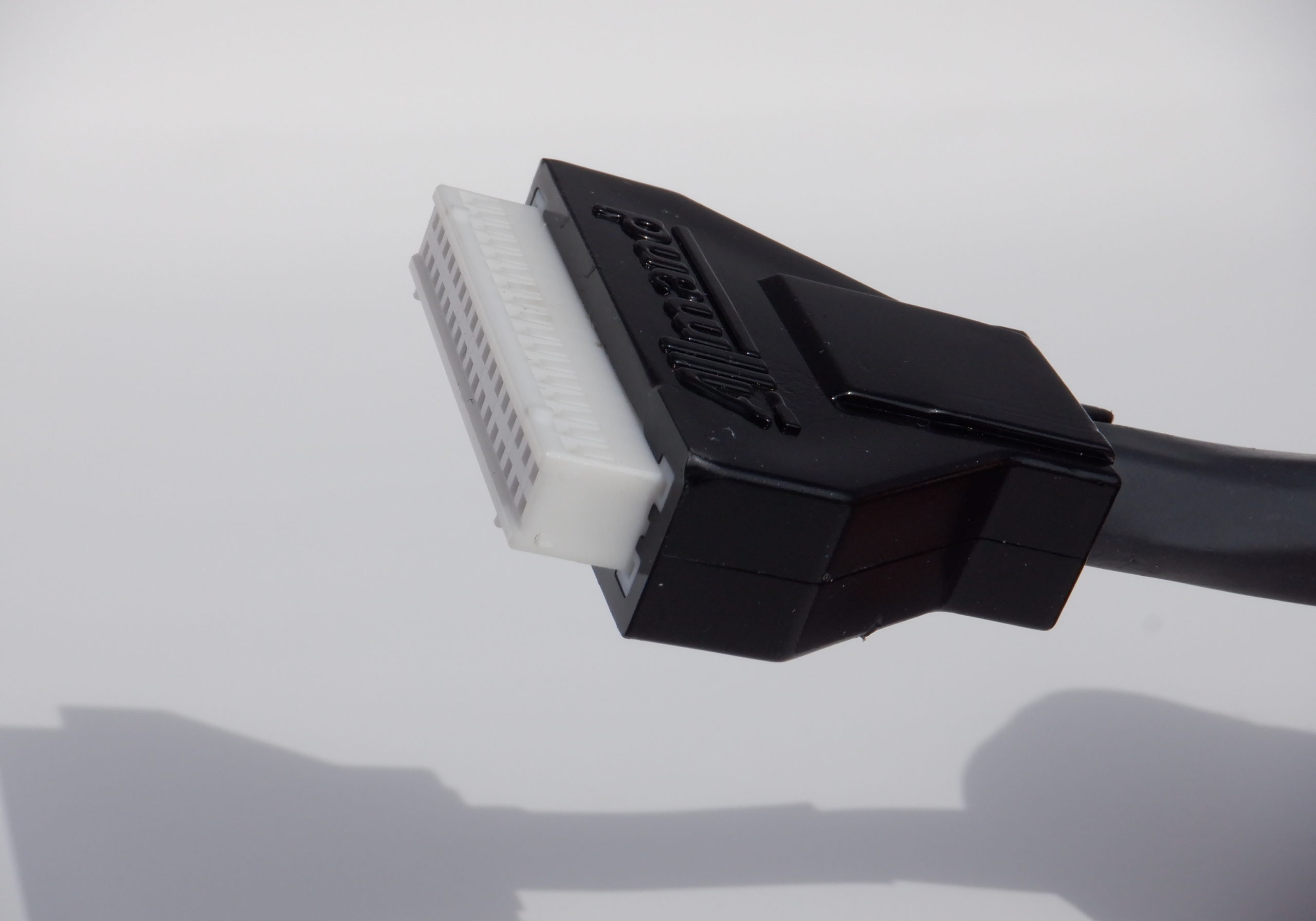

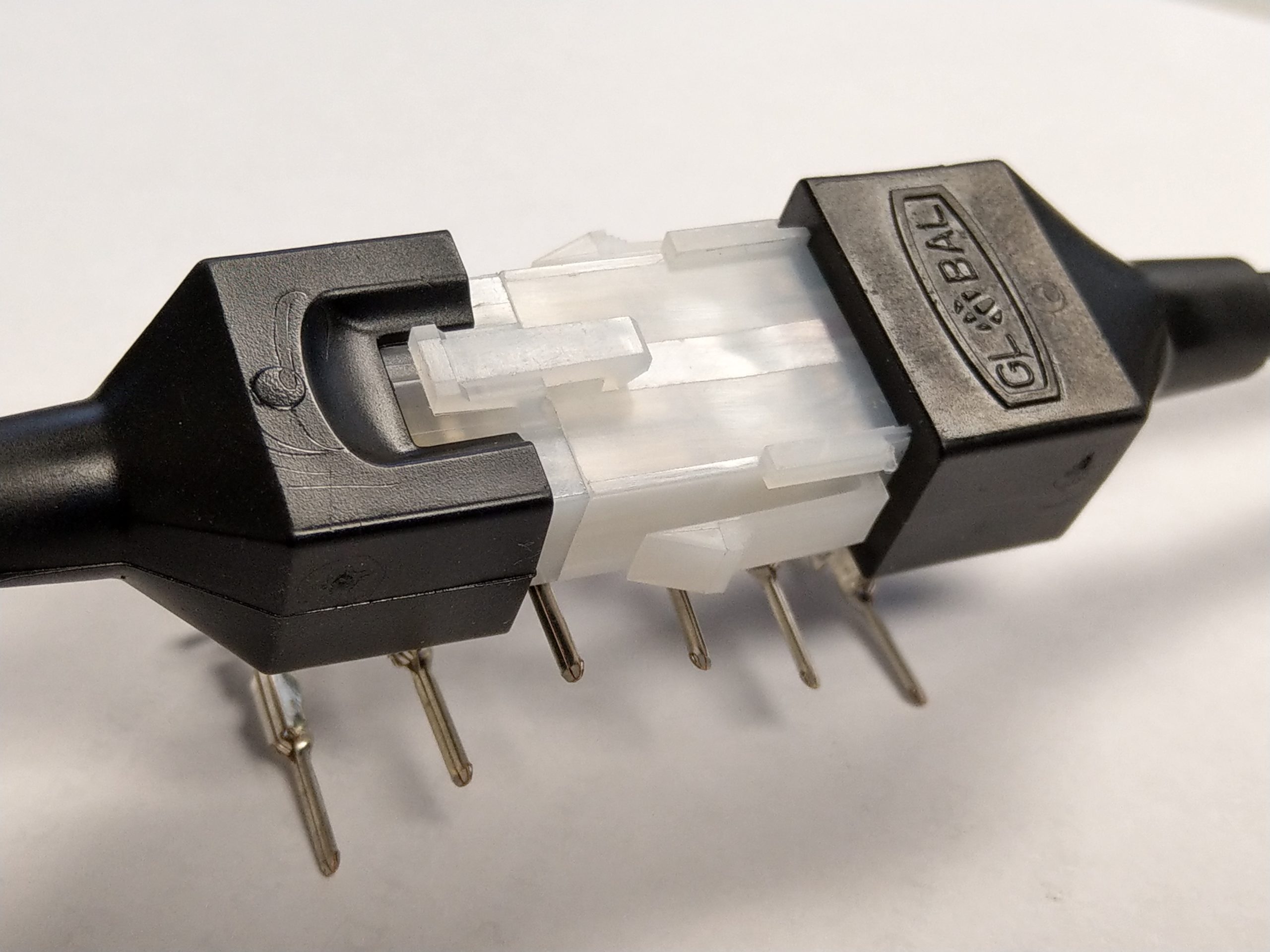

- Low pressure molding allows for the protection of sensitive circuit board component assemblies as well as increasing robustness of electrical connectors not meant to be overmolded.

- Low Pressure Molding improves interconnect reliability in Off-Road and Industrial applications increasing durability of non-sealed connection systems.

Combining your Low Pressure Molded assembly into a wire harness is a great way to assure reliability and durability for your application.