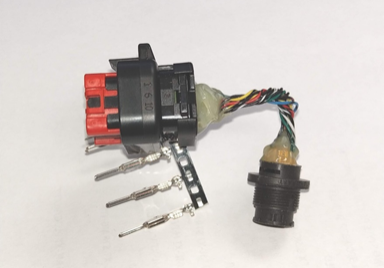

The Problem

Customer using this assembly for rugged outdoor Railroad application. Wires exposed and experiencing intermittent electrical issues due to damaged wires and water ingress using epoxied connectors. Needed to change not only gender, but to a completely different connector manufacture, and connect an electrical cable to standard GPS antenna for locomotive application. Customer was concerned about tooling cost and the EAU of only 150 pcs/year.

The Solution

The part was designed with customer input to assure understanding of preferred geometry and performance requirements. The customer logo was added to the overmold also giving it brand recognition. The resulting product met design and perfomance expectations. Additionally, working with our toolmakers we were able to keep the tooling cost reasonable and by running EAU's quarterly, assembly price is acceptable too.